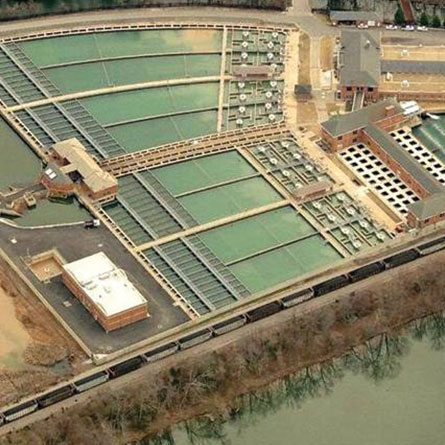

Richmond Water Treatment Plant Upgrades. Richmond, Virginia.

The current plant capacity is 132 million gallons per day, obtained via a series of coordinated upgrades of the previous 66 MGD capacity facility, and currently services the city and three surrounding counties. The work consisted of: 22 filter upgrades to high-rate capacity, pumping facility replacement and upgrades, intake controls and screening, chemical storage and feed facilities, as well as residuals handling facilities.

The most recent upgrades have included further upgrades of the flocculation/sedimentation basins; including new motors and VFDs for the flocculators; addition of plate settlers for enhanced solids removal performance; and replacement of the residuals collections systems for more efficient operation and upgrades of the filtered water pumping system (new 300 hp pump and VFD).

Services Performed

Project Highlights

Architecture

Architectural design has included the design of upgrades to the plant office space areas and exterior finishes to both new buildings added to the site and existing buildings.

Civil/Land Development

Civil design efforts have included work on plant piping, raw water conveyance channels and miscellaneous site improvements on the WTP site.

Electrical

Electrical design has included the design of a second electrical feeder to the plant, upgrades to the existing plant switchgear, new and upgraded pump motors, flocculator motors and VFDs for filtered water pumps and finished water pumps.

Geotechnical

Geotechnical design has included evaluation of foundations and excavations for basin rehabilitations and pump station sites, as well as modifications to earthen berms on the plant site.

Mechanical

Mechanical design has included both evaluation and design of raw water, filtered water and finished water pumping facilities, as well as numerous chemical feed systems in the WTP. HVAC improvements have also been incorporated into plant upgrades.

Structural

Structural design efforts consisted of the evaluation and design of upgrades to the existing concrete sedimentation basins, pump station clear wells and other structural infrastructure repairs, including structural design of a new finished water pump station located on the plant site.